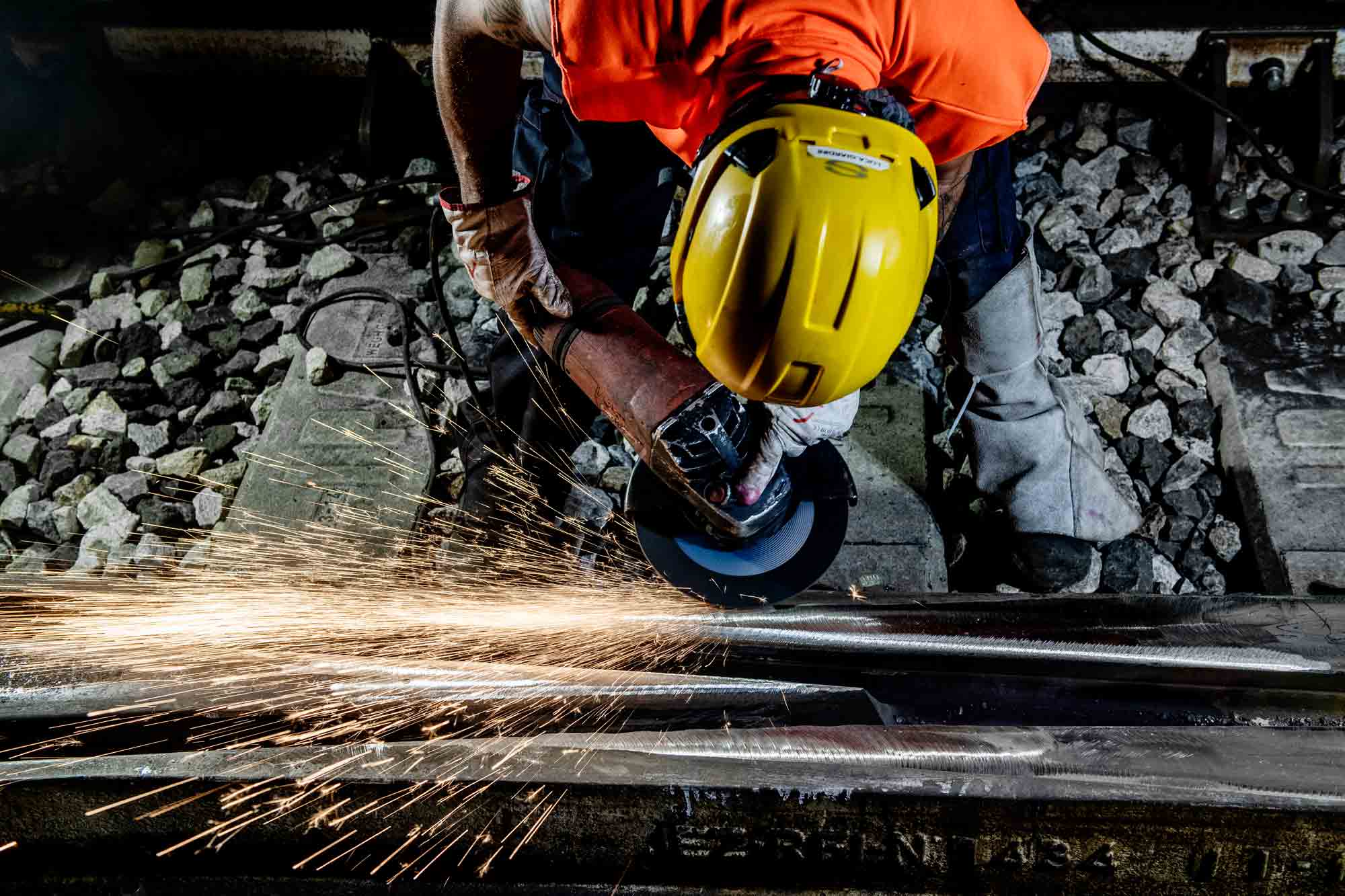

Frog repair in track possession

Fast action with minimum rail disruption

SAGA repairs both built-up crossings and austenitic manganese steel frogs with an automatic welding system.

All maintenance takes place directly on the track, in temporary possession coordinated with the client. This ensures virtually zero disruption to rail traffic. Work is carried out rapidly and precisely and once finished, trains can immediately run at maximum track speed.

The company is well aware of issues caused by on track maintenance and has a fleet of road-rail vehicles and teams ready to work across the country. They can reach any destination without using the railway and work on track like a true railway wagon.

Strengths

High output

All work is carried out in a timely manner with efficient logistics.

Flexibility

Work can be scheduled according to the length of possession.

Precision

The company has developed precision measuring tools in-house to ensure maintenance with the utmost accuracy.

Lower costs

Weld repair, rather than replacement, of frogs keeps costs down.

Minimum impact on rail traffic

Maintenance is carried out rapidly without affecting rail traffic.

Longer frog lifespan

Maintenance helps the turnout function better and increases the lifespan of each frog.